Cooling Water Systems

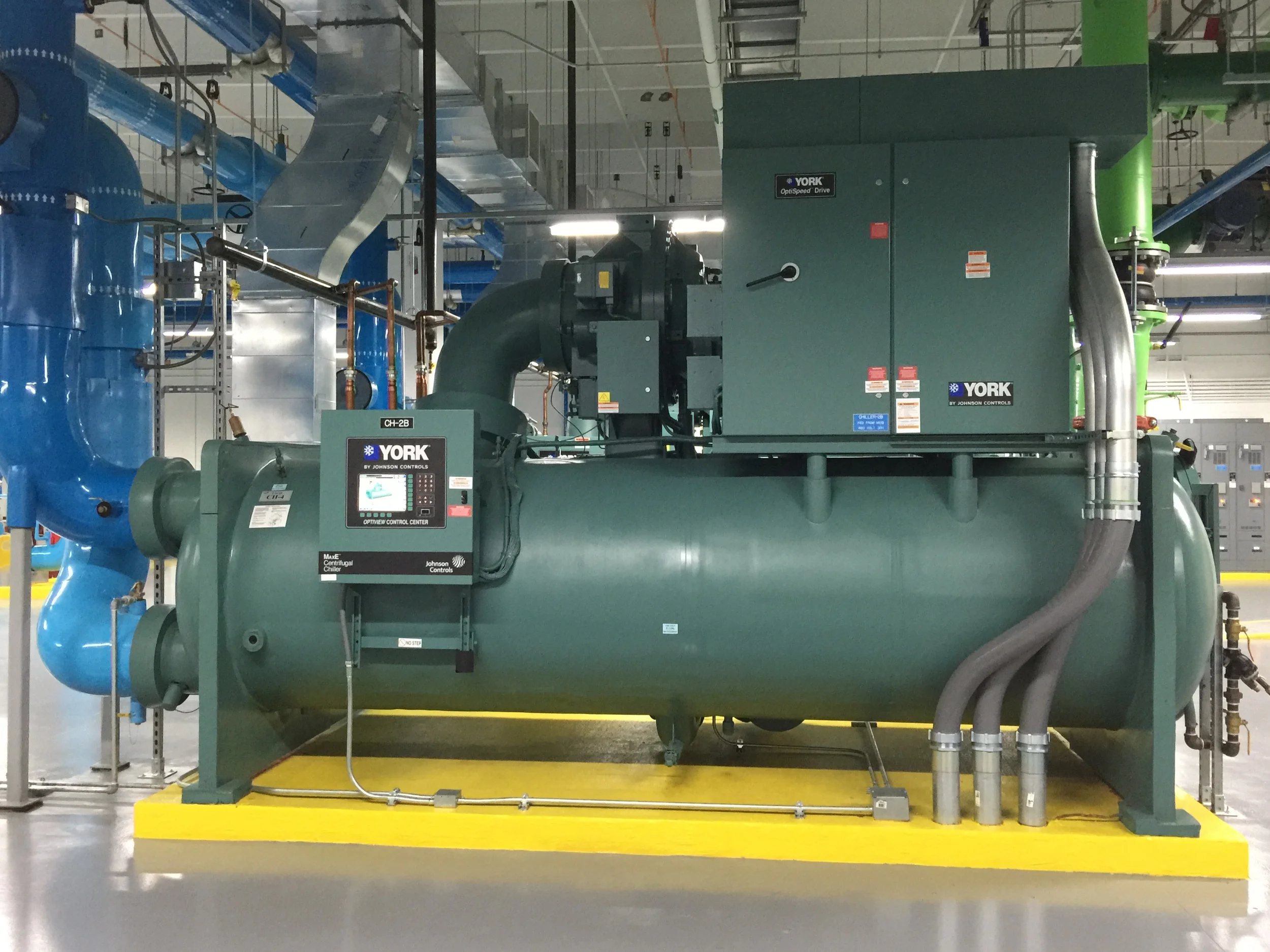

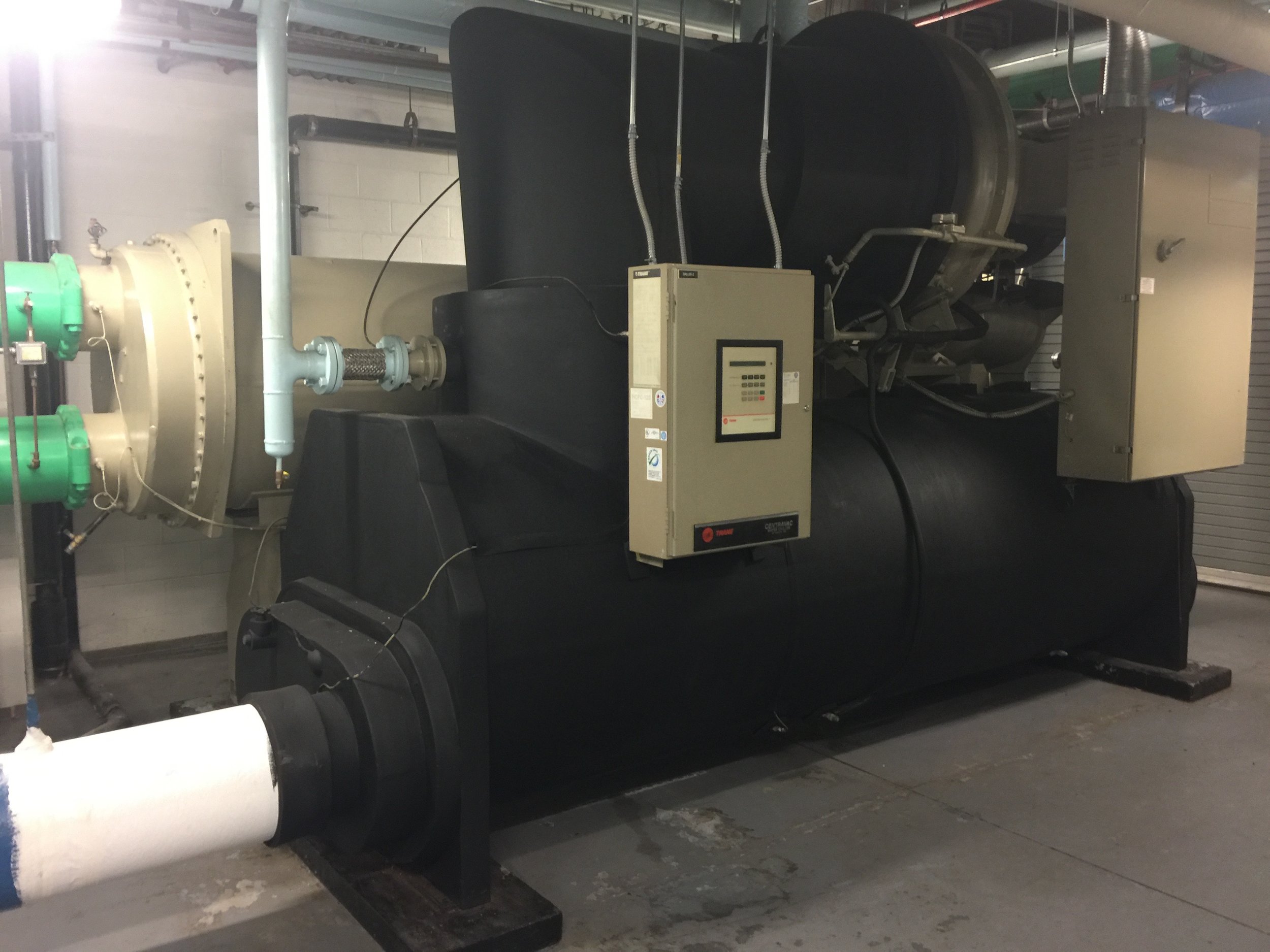

Cooling water systems provide an efficient and economical method to transfer heat and are thereby essential in a variety of applications, such as manufacturing processes, data center operations, and commercial building air conditioning. The design and implementation of our treatment programs are tailored to meet the individual needs of our clients in enhancing and maintaining heat transfer efficiency, minimizing utility costs, and maximizing the useful life of capital equipment.

Examples of the Services We Provide

- Precleaning of new piping and heat exchangers to remove mill scale and oil prior to start-up.

- Passivation of new galvanized towers to prevent white rust deposits.

- On-line, non-acid cleaning of rust deposits.

- Installation of control equipment and PVC piping systems for product feed and corrosion coupon stations.

- Condenser water treatment programs that prevent scale, minimize fouling deposits and generalized corrosion and prevent pitting.

- Remote monitoring via building management programs, internet or cellular connection.

- Program performance monitoring, including:

- On-site testing, including inhibitor components, total iron, copper, silica and hardness.

- On-site microbial testing using an ATP luminometer, which provides results in 15 seconds, rather than the 24-48 hours traditional dip slides require.

- Coupon studies utilizing corrosion, deposit and microbial coupons.

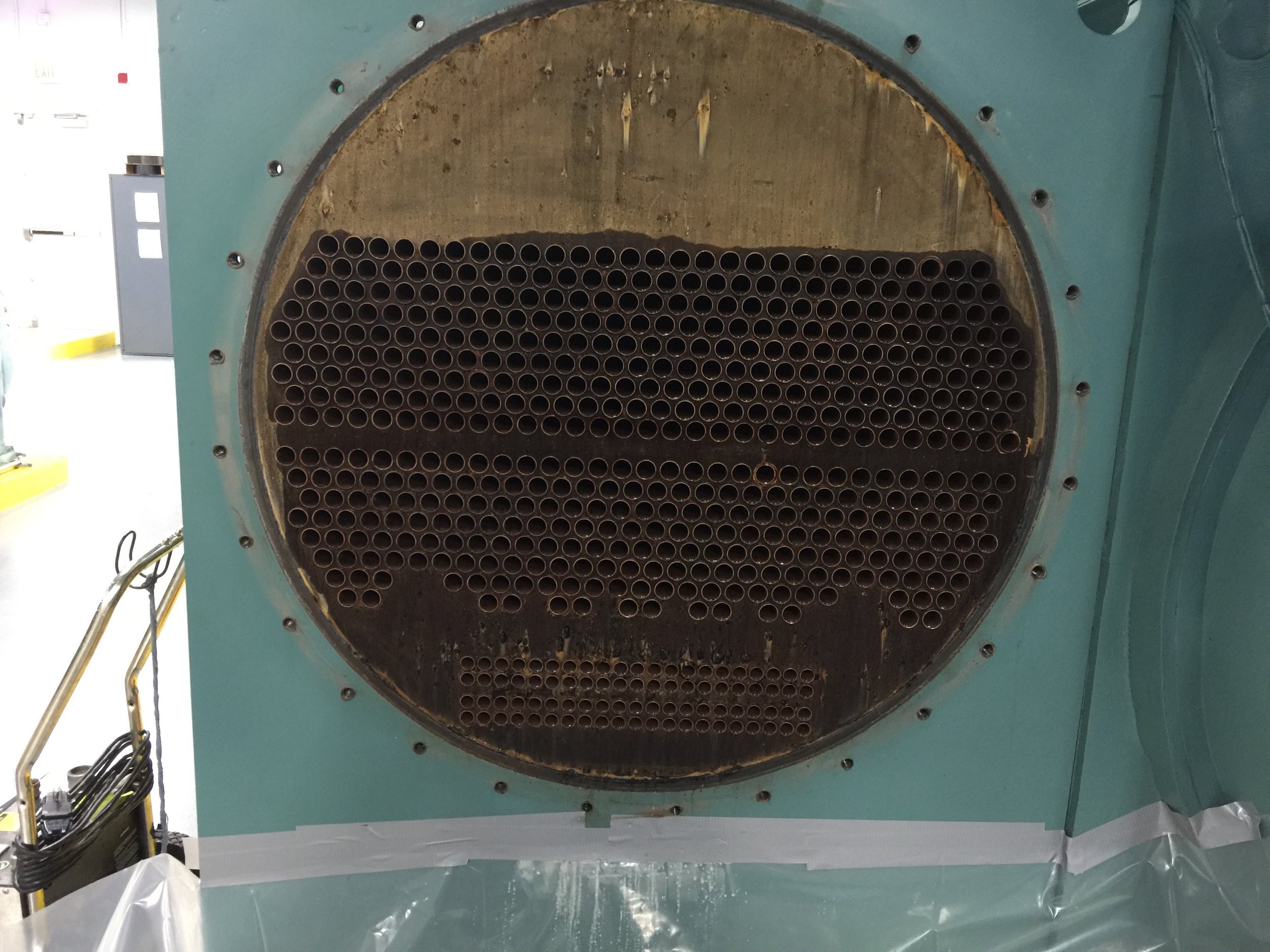

- Heat exchanger approach studies.

- Internal equipment inspection.

- Deposit and microbial analyses.

- Cooling tower sterilization and pressure washer cleaning